Aluminum Oxide Sanding Belts(also known as AO sanding belt)

533x75mm 3x21inch

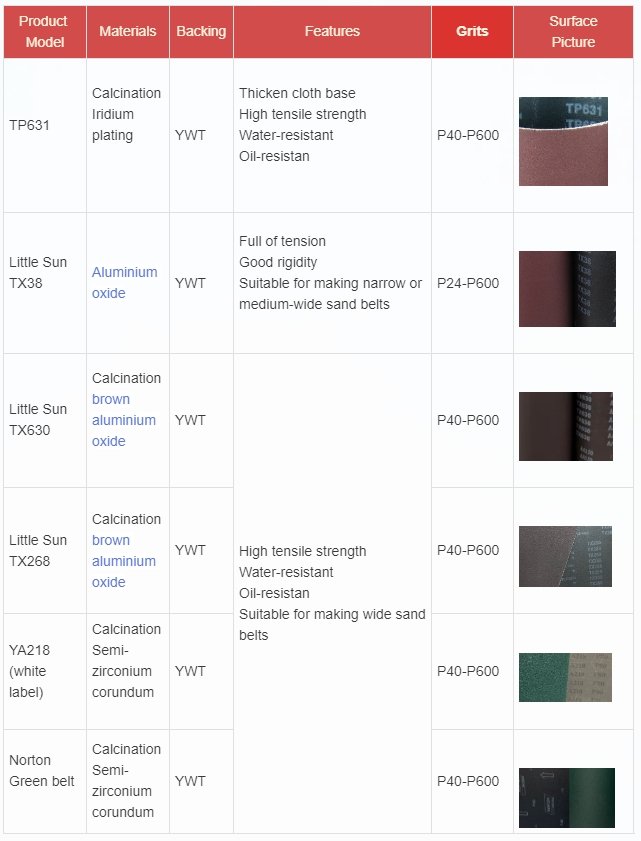

Technical Specifications:

-

Abrasive Type:Aluminium oxide stacked

- Brand:little sun

-

Backing Material: YWT

-

Grit Range: 60#-600# for coarse to fine grinding

-

Belt Sizes:

-

Standard Widths: 10mm – 120mm

-

Custom Sizes: Available from 330mm to 9000mm lengths

-

Common Lengths:

1 x 30 inch(25x762mm)1 x 42 inch(25x1067mm)2 x 36 inch2 x 42 inch(50x1067mm)2 x 48 inch(50x1220mm)50x2100mm2 x 60 inch2 x 72 inch2 x 132 inch2½ x 60 inch3 x 18 inch(75x457mm)3 x 21 inch(75x533mm)3 x 24 inch (75x610mm)3 x 79 inch3 x 132 inch4 x 24 inch (100x610mm)4 x 36 inch (100x915mm)4 x 48 inch (100x1220mm)100x2100mm4 x 54 inch6 x 48 inch6 x 80 inch6 x 89 inch

-

Versatile, Durable, and Engineered for Multi-Material Excellence

Precision Meets Versatility

Whether you’re shaping hardwood panels, deburring carbon steel, or prepping surfaces on titanium alloys, Aluminum Oxide Sanding Belts deliver dependable performance across a broad range of applications. Designed for industrial and professional users who require both efficiency and consistency, these belts strike the perfect balance between aggressive material removal and refined finishing.

Ideal for multiple industries and materials:

Wood & lacquered panels (furniture and cabinetry)

Plastic surfaces (molded parts, casings)

Carbon steel & stainless steel (machinery, pipes)

Cobalt and titanium alloys (aerospace, medical)

Engineered with Performance in Every Layer

High-Grade Aluminum Oxide Abrasive Grain

The core of every belt features precision-coated aluminum oxide abrasive, a material renowned for its sharp cutting edges, thermal resistance, and longer operational life. Whether you’re using coarse grits for rapid material removal or finer grits for polishing, aluminum oxide consistently delivers clean, accurate results.

Tough, Flexible Backing Options

Available in cloth, paper, and polyester-backed variations to match the needs of your specific job:

Polyester cloth: tear-resistant and ideal for high-pressure grinding

Paper backing: lightweight and cost-efficient for less aggressive jobs

Cotton/cloth: excellent for curved surfaces and belt flexibility

Strong Resin Bond System

Grains are securely adhered using an industrial-grade resin bond, ensuring the abrasive remains intact under high-speed or high-pressure operations. This also reduces grain shedding and increases grit stability, directly improving both safety and productivity.

Key Benefits That Set Us Apart

Why Choose Our Aluminum Oxide Sanding Belts?

Unlike generic sanding belts that wear quickly or clog under pressure, our aluminum oxide belts are engineered with an optimized abrasive structure that balances cutting aggressiveness and heat control. That means less downtime for replacements, fewer defects, and better ROI on every belt.

Common Use Case Scenarios

Task Type Recommended Grit Range Notes

Heavy stock removal 24 – 40 For weld grinding and beveling

General purpose sanding 60 – 120 For wood, steel, and plastic prep work

Fine finishing or polishing 180 – 400+ For cosmetic surfaces, lacquer sanding

Let Your Workflow Flow Smoother

When productivity matters, and precision counts, professionals trust aluminum oxide for its adaptability, durability, and cost-efficiency. Whether you’re in metal fabrication, furniture manufacturing, or high-precision component finishing, our belts help you achieve the results your clients demand.

Looking to reduce changeovers and enhance finish consistency?

Reviews

There are no reviews yet.