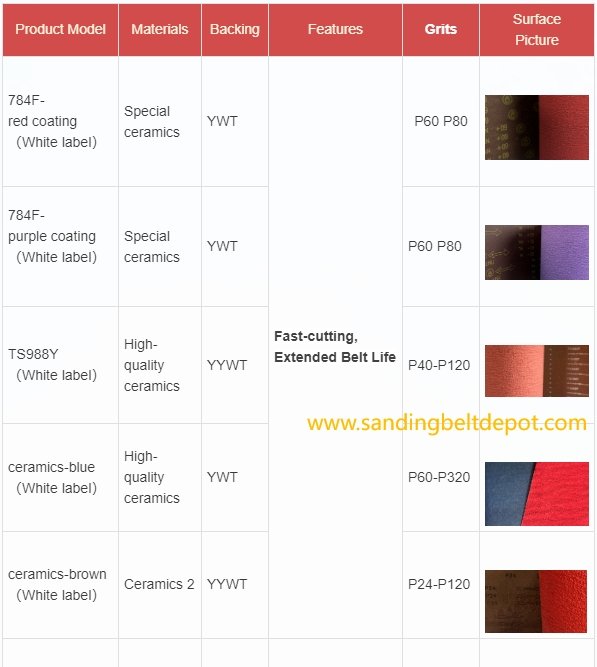

high-quality Ceramic For hard metal grinding, such as: super hard titanium alloy, high carbon chromium stainless steel, high molybdenum stainless steel, castings, hard nickel bronze, chrome alloy hardware, gray cast iron. Ceramic abrasive series products are especially suitable for grinding stainless steel, high-alloy steel, titanium alloy and nickel-based alloy

Technical Specifications:

-

Abrasive Type:high-quality Ceramic Materials

- Brand:(White label、PG966M Blue cloth base)

-

Backing Material: Heavy-duty YWT cloth (0.8mm thickness)

-

Grit Range: 60#-80#-120#-240#-320# for coarse to fine grinding

-

Heat Resistance: Withstands 600°F continuous operation

-

Belt Sizes:

-

Standard Widths: 10mm – 120mm

-

Custom Sizes: Available from 330mm to 9000mm lengths

-

Common Lengths:

1 x 30 inch(25x762mm) Ceramicsanding belts1 x 42 inch(25x1067mm) Ceramicsanding belts2 x 36 inch Ceramicsanding belts2 x 42 inch(50x1067mm) Ceramic sanding belts2 x 48 inch(50x1220mm) Ceramic sanding belts50x2100mm Ceramic sanding belts2 x 60 inch Ceramic sanding belts2 x 72 inch Ceramic sanding belts2 x 132 inch Ceramic sanding belts2½ x 60 inch Ceramic sanding belts3 x 18 inch(75x457mm) Ceramic sanding belts3 x 21 inch(75x533mm) Ceramic sanding belts3 x 24 inch (75x610mm)Ceramic sanding belts3 x 79 inch Ceramic sanding belts3 x 132 inch zirconia sanding belts4 x 24 inch (100x610mm) Ceramic sanding belts4 x 36 inch (100x915mm) Ceramic sanding belts4 x 48 inch (100x1220mm)Ceramic sanding belts100x2100mm Ceramic sanding belts4 x 54 inch Ceramic sanding belts6 x 48 inch Ceramic sanding belts6 x 80 inch Ceramic sanding belts6 x 89 inch Ceramic sanding belts

-

Proven Applications:

✔ Aerospace Components:

-

Turbine blade finishing

-

Titanium alloy edge blending

✔ Automotive Manufacturing: -

Stainless steel exhaust systems

-

Cast iron brake components

✔ Heavy Fabrication: -

Weld seam leveling (Inconel/Nickel alloys)

-

Forging flash removal

Competitive Advantages:

1. 3X Longer Service Life

The interlocking grain structure ensures 300% more durability than standard zirconia belts, reducing changeover frequency and consumable costs.

2. High Stock Removal Rates

Engineered for aggressive material removal:

-

40% faster than aluminum oxide on 304 stainless

-

Zero-loading on gummy materials like bronze

3. Precision Surface Finish

Consistent scratch patterns (RA 20-45μin) eliminate secondary polishing steps on:

-

Investment castings

-

Precision machined parts

4. Versatile Cooling Options

Special coating allows:

▷ Dry grinding up to 600°F

▷ Wet grinding with soluble oils

Industry-Specific Solutions:

For Foundries:

-

Removes parting lines from steel castings 50% faster

-

No burning on thin-section ductile iron

For CNC Shops:

-

Ideal for deburring machined aerospace alloys

-

Maintains dimensional accuracy

Customization Options:

-

Tailored grain concentrations for specific alloys

-

Reinforced edges for robotic applications

-

Anti-static versions for automated lines

Technical Comparison:

| Feature | Ceramic belt PG966M | Standard Zirconia belt |

|---|---|---|

| Cut Rate | ★★★★★ | ★★★☆☆ |

| Life Span | 300-400hrs | 100-150hrs |

| Heat Tolerance | 600°F | 400°F |

| Best For | Superalloys | Mild steel |

Ordering Information:

-

MOQ: 200 belts (custom sizes)

-

Standard sizes ship in 5-8 days

-

Request sample kit with 3 grit options

FAQ:

Q: How does ceramic outperform zirconia on titanium?

A: The microcrystalline structure stays sharper on Ti-6Al-4V, reducing heat buildup that causes work hardening.

Q: Can these belts handle robotic grinding?

A: Yes – our X-series backing resists stretching for automated applications.

Reviews

There are no reviews yet.