High-Performance Ceramic Sanding Belt 784F for Precision Metal Finishing

Brand: white label ((Premium 3M Cubitron 784F Sanding Belts Alternative))

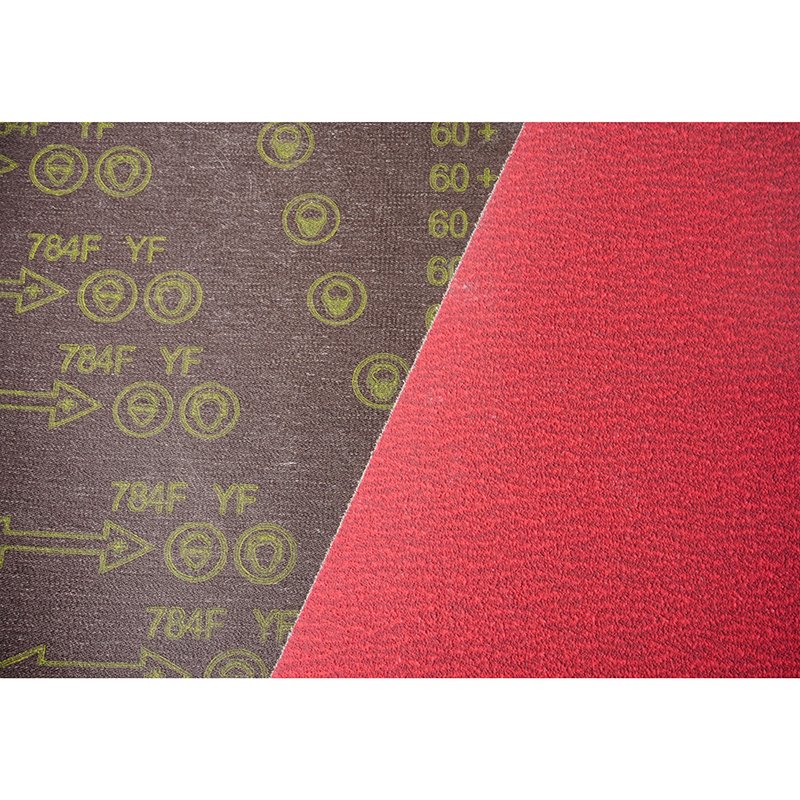

Superior Construction: Featuring a heavy-duty YWT backing that’s not only waterproof and heat-resistant but also engineered for high-pressure metal grinding applications. As a result, these belts deliver exceptional durability and consistent performance even under extreme conditions.

Available Specifications:

-

Width Range: 10-120mm

-

Length Range: 330-9000mm

-

Standard Sizes: Including 533x75mm (3×21″), 457x75mm (3×18″), 915x100mm (4×36″) Additionally, we offer 762x25mm (1×30″), 1067x25mm (1×42″), and 1820x50mm (2×72″)

-

Grit Options: 60# & 80#

-

Minimum Order: 200+ pieces for first-time orders

Key Advantages:

-

Specifically designed for hard metal grinding including:

-

Titanium alloys

-

High-carbon chromium stainless steel

-

Nickel bronze alloys Moreover, they’re ideal for chrome hardware and cast iron

-

-

Unlike conventional belts, our ceramic abrasive series:

-

Significantly extends belt service life (up to 3x longer)

-

Dramatically improves cutting efficiency

-

Features advanced anti-clogging coating

-

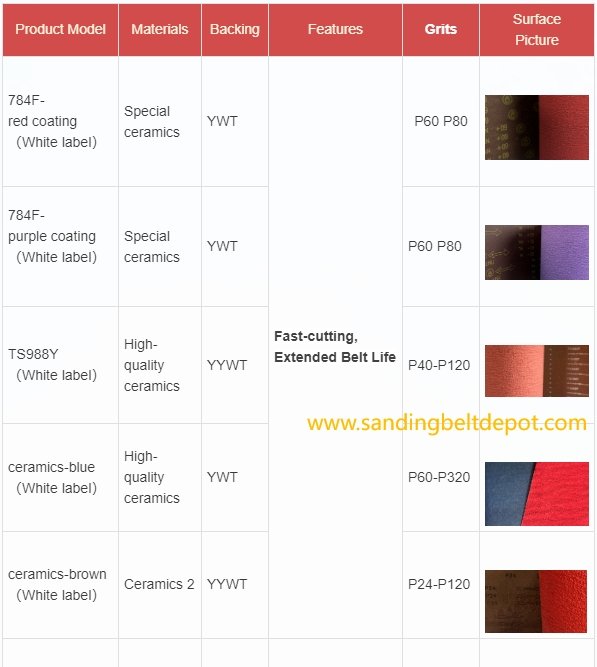

Product Series Table:

Appliction:

High-Quality Ceramic Sanding belt 784F For hard metal grinding, such as: super hard titanium alloy, high carbon chromium stainless steel, high molybdenum stainless steel, castings, hard nickel bronze, chrome alloy hardware, gray cast iron. Ceramic abrasive series products are especially suitable for grinding stainless steel, high-alloy steel, titanium alloy and nickel-based alloy Greatly extend the service life of the abrasive belt and improve cutting efficiency, high heat resistance, super-coated anti-clogging, water and oil resistance, dry grinding and water grinding.

The case shows:

What Sizes Are Ceramic Sanding Belts Available In?

Custom Solutions Available: For specialized requirements, we offer:

-

Fully customizable dimensions

-

Zirconia-alternative formulations

-

Instant online quoting via our [Custom Order Form]

Technical FAQ:

Q: Ceramic vs Zirconia Sanding Belts: Which One Should You Choose?

A: While both are exceptional, ceramic abrasives:

-

Typically last 30% longer on super-alloys

-

Generally maintain sharper cutting edges

-

Conversely, zirconia may be preferable for heavy removal

Reviews

There are no reviews yet.