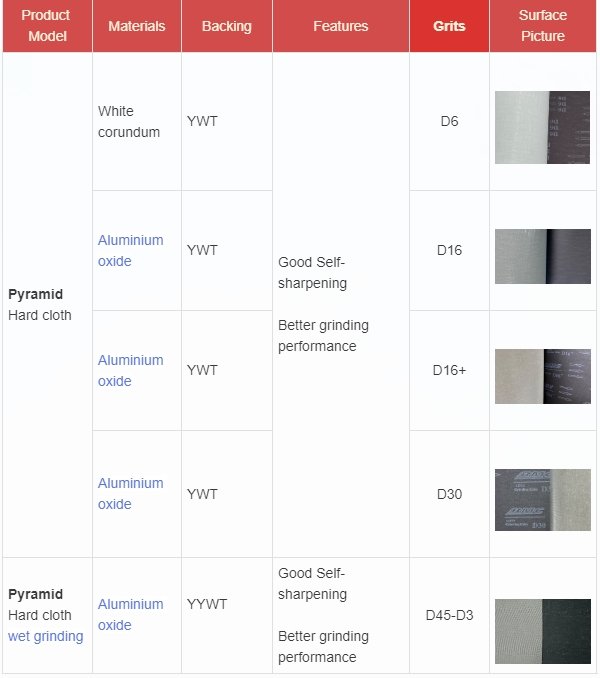

Technical Specifications:

-

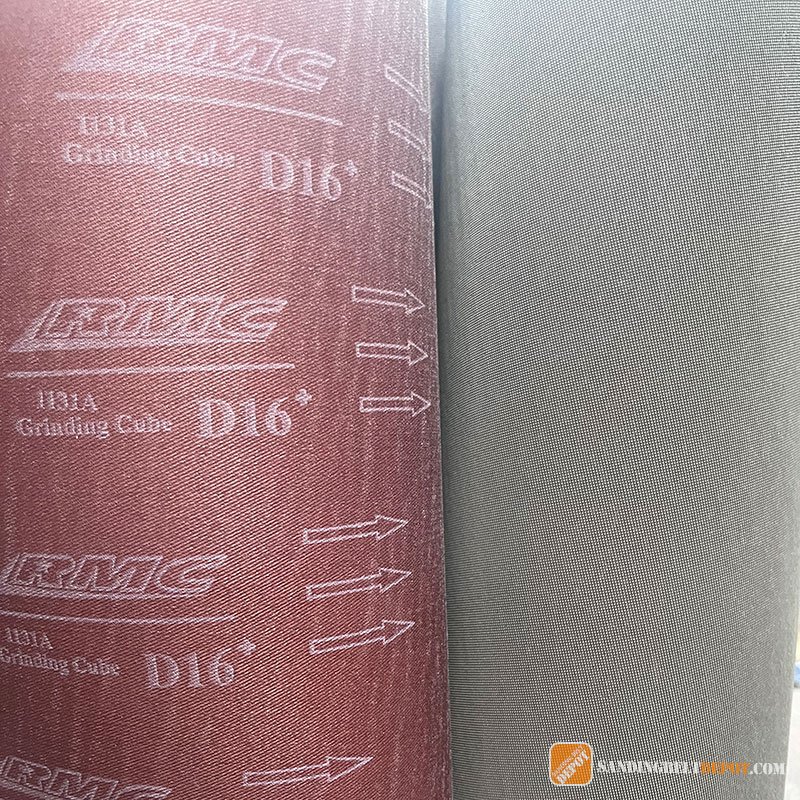

Abrasive Type: Pyramid soft cloth Sanding Belt D16+(Trizact Finishing Belts Alternative)

- Brand:RMC

-

Backing: JWT Aluminium oxide soft cloth

-

Grit Range: D16+ (approximate 1200 grit)

-

Splice Types: (Default type:butt joint)Overlap, butt joint, S-joint for low vibration and smooth running

-

Available Shapes: Narrow belts, wide belts, file belts, and segmented belts,Whole roll raw material

-

Belt Sizes:

-

Standard Widths: 10mm – 120mm(custom available)

-

Custom Sizes: Available from 330mm to 9000mm lengths(custom available)

-

Common Lengths:

1 x 30 inch(25x762mm)1 x 42 inch(25x1067mm)2 x 36 inch2 x 42 inch(50x1067mm)2 x 48 inch(50x1220mm)50x2100mm2 x 60 inch2 x 72 inch2 x 132 inch2½ x 60 inch3 x 18 inch(75x457mm)3 x 21 inch(75x533mm)3 x 24 inch (75x610mm)3 x 79 inch3 x 132 inch4 x 24 inch (100x610mm)4 x 36 inch (100x915mm)4 x 48 inch (100x1220mm)100x2100mm4 x 54 inch6 x 48 inch6 x 80 inch6 x 89 inch

-

Pyramid Precision: Advanced Trizact-Style Sanding Belts

Engineered for Professionals Who Demand More

Experience breakthrough performance in fine surface finishing with our Pyramid Structure Sanding Belts—an enhanced alternative to conventional abrasives, designed for makers, fabricators, and industrial users who refuse to compromise on consistency, efficiency, or quality.

Why Our Pyramid Belts Stand Out

Micro-Structured Abrasive Geometry

Built with 3D pyramid-shaped abrasive clusters, each layer wears down gradually to reveal fresh, sharp cutting edges—delivering a uniform finish from start to end.

Cooler Cuts, Less Burn

The unique spacing and structure of our belts allow for superior heat dissipation, helping reduce thermal damage and maintain material integrity—ideal for stainless steel, titanium, and carbon composites.

Lasts Up to 5X Longer

Unlike traditional belts that degrade unevenly, the multi-layer pyramid abrasives maintain cutting performance much longer, reducing changeovers and increasing production efficiency.

Finish-Grade Versatility

Perfect for metal fabrication, pre-plating polish, knife making, medical components, and precision electronics. Whether flat grinding or contour shaping, these belts ensure a flawless surface every time.

The Smart Choice for Serious Finishers

Where accuracy, consistency, and economy matter, Pyramid Structure Belts deliver measurable value. Outperform traditional aluminum oxide or ceramic belts in both finish quality and lifecycle cost—making them a superior investment for demanding applications.

Upgrade Your Finish. Upgrade Your Process.

Choose belts that go further, grind cooler, and finish sharper—because when surface perfection is the goal, compromise is not an option.

Reviews

There are no reviews yet.