Technical Specifications:

-

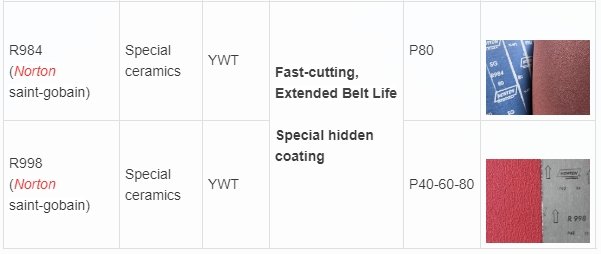

Abrasive Type: Special Ceramic

- Brand: Norton saint-gobain R998

-

Backing Material: Heavy-duty YWT cloth (0.8mm thickness)

-

Grit Range: 40# – 60#-80# for coarse to fine grinding

-

Heat Resistance: Withstands 600°F continuous operation

-

Belt Sizes:

-

Standard Widths: 10mm – 120mm

-

Custom Sizes: Available from 330mm to 9000mm lengths

-

Common Lengths:

1 x 30 inch(25x762mm) Ceramicsanding belts1 x 42 inch(25x1067mm) Ceramicsanding belts2 x 36 inch Ceramicsanding belts2 x 42 inch(50x1067mm) Ceramic sanding belts2 x 48 inch(50x1220mm) Ceramic sanding belts50x2100mm Ceramic sanding belts2 x 60 inch Ceramic sanding belts2 x 72 inch Ceramic sanding belts2 x 132 inch Ceramic sanding belts2½ x 60 inch Ceramic sanding belts3 x 18 inch(75x457mm) Ceramic sanding belts3 x 21 inch(75x533mm) Ceramic sanding belts3 x 24 inch (75x610mm)Ceramic sanding belts3 x 79 inch Ceramic sanding belts3 x 132 inch zirconia sanding belts4 x 24 inch (100x610mm) Ceramic sanding belts4 x 36 inch (100x915mm) Ceramic sanding belts4 x 48 inch (100x1220mm)Ceramic sanding belts100x2100mm Ceramic sanding belts4 x 54 inch Ceramic sanding belts6 x 48 inch Ceramic sanding belts6 x 80 inch Ceramic sanding belts6 x 89 inch Ceramic sanding belts

-

Proven Applications:

✔ Aerospace Components:

-

Turbine blade finishing

-

Titanium alloy edge blending

✔ Automotive Manufacturing: -

Stainless steel exhaust systems

-

Cast iron brake components

✔ Heavy Fabrication: -

Weld seam leveling (Inconel/Nickel alloys)

-

Forging flash removal

Competitive Advantages:

1. 3X Longer Service Life

The interlocking grain structure ensures 300% more durability than standard zirconia belts, reducing changeover frequency and consumable costs.

2. High Stock Removal Rates

Engineered for aggressive material removal:

-

40% faster than aluminum oxide on 304 stainless

-

Zero-loading on gummy materials like bronze

3. Precision Surface Finish

Consistent scratch patterns (RA 20-45μin) eliminate secondary polishing steps on:

-

Investment castings

-

Precision machined parts

4. Versatile Cooling Options

Special coating allows:

▷ Dry grinding up to 600°F

▷ Wet grinding with soluble oils

Industry-Specific Solutions:

For Foundries:

-

Removes parting lines from steel castings 50% faster

-

No burning on thin-section ductile iron

For CNC Shops:

-

Ideal for deburring machined aerospace alloys

-

Maintains dimensional accuracy

Customization Options:

-

Tailored grain concentrations for specific alloys

-

Reinforced edges for robotic applications

-

Anti-static versions for automated lines

Technical Comparison:

| Feature | Norton R998 Ceramic belt | Standard Zirconia belt |

|---|---|---|

| Cut Rate | ★★★★★ | ★★★☆☆ |

| Life Span | 300-400hrs | 100-150hrs |

| Heat Tolerance | 600°F | 400°F |

| Best For | Superalloys | Mild steel |

Ordering Information:

-

MOQ: 200 belts (custom sizes)

-

Standard sizes ship in 5-8 days

-

Request sample kit with 3 grit options

FAQ:

Q: How does ceramic outperform zirconia on titanium?

A: The microcrystalline structure stays sharper on Ti-6Al-4V, reducing heat buildup that causes work hardening.

Q: Can these belts handle robotic grinding?

A: Yes – our X-series backing resists stretching for automated applications.

Reviews

There are no reviews yet.