Unmatched Durability & Cutting Performance

Engineered for demanding metalworking applications, our Zirconia Sanding Belts deliver exceptional abrasion resistance and material removal rates—ideal for high-volume production environments. The self-sharpening zirconia abrasive grains maintain aggressive cutting edges longer than conventional aluminum oxide belts, reducing downtime and consumable costs.

Key Advantages:

✔ 30% Longer Lifespan – Withstands intense grinding of stainless steel, carbon steel, and alloys

✔ High Stock Removal – 50% faster cutting vs. standard Aluminum Oxide belts (tested at 50N pressure)

✔ Heat-Resistant Bonding – Stable performance up to 260°C (500°F) without grain shedding

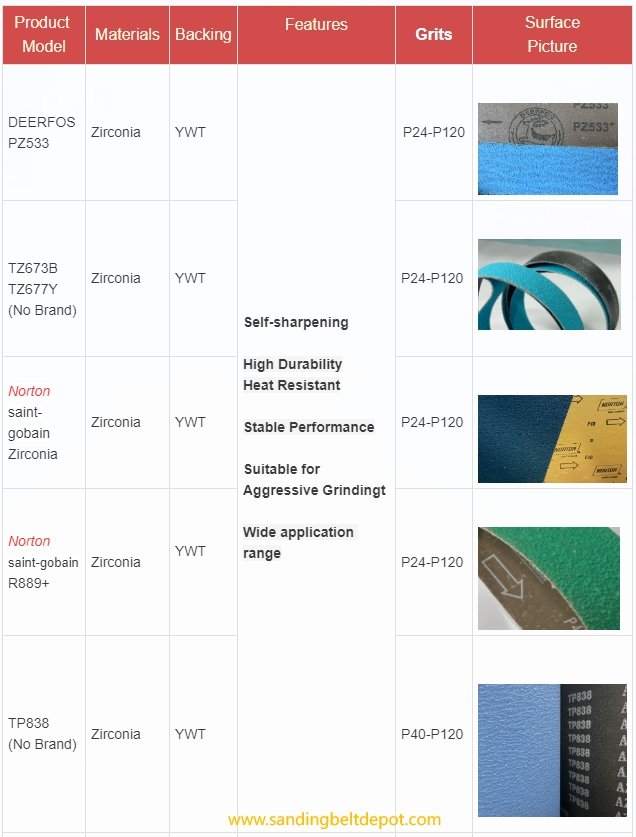

Product Specifications

Model :PZ533-330X10 Industrial Series

Size 330 x 10mm (13″ x 0.4″)

Abrasive Premium Zirconia Alumina (ZrO₂ 65%)

Backing X-Weight Polyester-Cloth Hybrid

Grit Range 40 / 60 / 80 / 120 / 150

Max Speed 30 m/s (5,900 SFPM)

Tensile Strength 900N (Kevlar-reinforced joints)

Industrial Applications

Precision Deburring – Smooth edges on machined automotive components

Weld Seam Leveling – Efficiently blends stainless steel welds (80-grit recommended)

Surface Conditioning – Prepares metal surfaces for coating/painting

High-Pressure Grinding – Compatible with pneumatic and electric belt sanders

Technical Highlights

Electrostatic Coating Process Ensures 95%+ grain density for consistent performance

Anti-Clog Design Open-coat structure minimizes loading with sticky metals (e.g., aluminum)

ISO 6344 Certified Meets international standards for abrasive product safety

Pro Tip: For titanium grinding, use 60-grit belts with coolant to prevent overheating.

Why Choose Our 330x10mm Belts?

Proven in Aerospace & Automotive – Trusted by Tier-1 suppliers for critical finishing

Cost-Efficient – Processes 35% more material per belt vs. competitors

Global Compliance , no hazardous materials

Request Samples – Test in your production line with 10 free belts (MOQ 100 units).

Reviews

There are no reviews yet.