Zirconia sanding belts, also known as zirconia abrasive belts or zirconium corundum belts, are a high-performance solution for aggressive grinding and deburring of metal surfaces. Designed specifically for medium to heavy material removal, these belts excel in industrial settings such as small to mid-sized metalworking shops, polishing workshops, and automotive parts manufacturing facilities. With a unique self-sharpening structure and superior toughness, zirconia belts are ideal for use on stainless steel, carbon steel, alloy steel, and cast iron, especially in high-pressure applications.

Key Features of Zirconia Abrasive Belts

- Self-Sharpening Grains: Zirconia alumina features a friable structure that continually fractures during use, exposing fresh cutting edges and maintaining high grinding efficiency.

- High Stock Removal: Excellent for aggressive applications such as weld seam removal, heavy deburring, and oxide/rust layer elimination.

- Long Belt Life: Outlasts aluminum oxide belts by 2–3 times, reducing the frequency of belt change and downtime.

- Cool Grinding Action: The active grinding additives (grinding aids) help reduce heat generation, minimizing the risk of burning workpieces.

- Strong Backing: Reinforced with heavy-duty polyester or Y-weight cloth for stability during high-tension operations.

- Water & Oil Resistant: Suitable for both dry and wet grinding applications, maintaining performance in harsh environments.

Technical Specifications:

-

Abrasive Type: Zirconium corundum

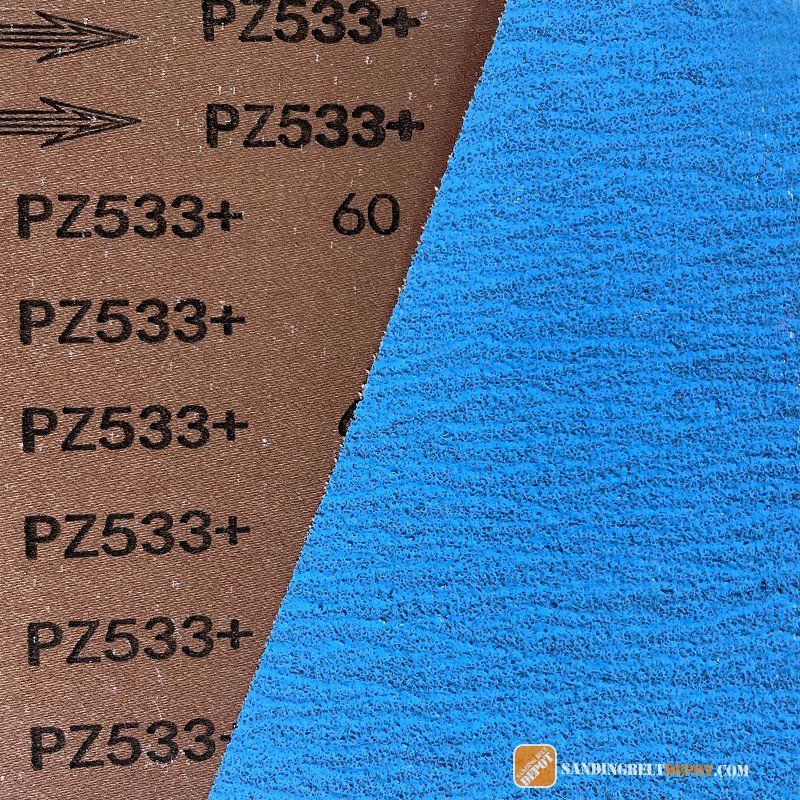

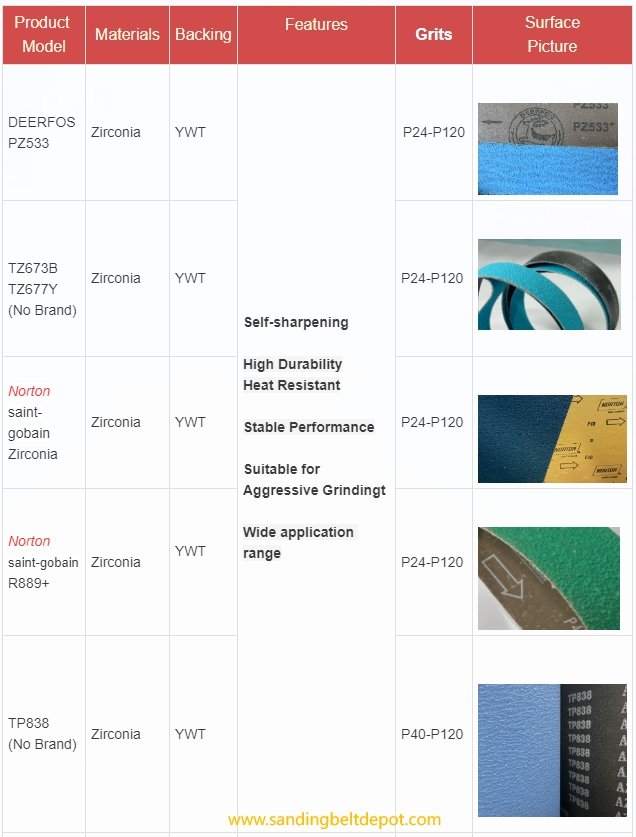

- Brand: White Label (Deerfos PZ533 Alternative)

-

Backing: Y-weight polyester, durable and tear-resistant

-

Grit Range: 40# – 60#-80# -120# for coarse to fine grinding

-

Splice Types: (Default type:butt joint)Overlap, butt joint, S-joint for low vibration and smooth running

-

Available Shapes: Narrow belts, wide belts, file belts, and segmented belts,Whole roll raw material

-

Belt Sizes:

-

Standard Widths: 10mm – 120mm(custom available)

-

Custom Sizes: Available from 330mm to 9000mm lengths(custom available)

-

Common Lengths:

1 x 30 inch(25x762mm)1 x 42 inch(25x1067mm)2 x 36 inch2 x 42 inch(50x1067mm)2 x 48 inch(50x1220mm)50x2100mm2 x 60 inch2 x 72 inch2 x 132 inch2½ x 60 inch3 x 18 inch(75x457mm)3 x 21 inch(75x533mm)3 x 24 inch (75x610mm)3 x 79 inch3 x 132 inch4 x 24 inch (100x610mm)4 x 36 inch (100x915mm)4 x 48 inch (100x1220mm)100x2100mm4 x 54 inch6 x 48 inch6 x 80 inch6 x 89 inch

-

Target Applications Zirconia sanding belts are engineered for demanding grinding tasks and are widely used in:

- Weld Seam Removal: Excellent for removing welds from stainless steel tanks, piping, and structural components.

- Deburring Cast and Forged Parts: Ideal for removing flashing and burrs from cast iron and forged alloy components.

- Rust and Oxide Layer Stripping: Quickly eliminates corrosion and scale layers from metal surfaces.

- Metal Surface Preparation: Prepares surfaces for painting, coating, or fine polishing in automotive and fabrication shops.

- Tank and Vessel Manufacturing: Efficient grinding of curved or flat surfaces with wide belt configurations.

Suitable Materials

- Stainless steel (304/316)

- Alloy steel and carbon steel

- Cast iron and gray iron

- High-manganese steel

- Nickel- and chromium-based alloys

- Automotive-grade metal parts

Who Should Use Zirconia Sanding Belts?

- Metal polishing workshops

- Mid-sized metal fabrication plants

- Automotive components manufacturers

- Industrial repair facilities

- Machining shops handling forged or cast components

Advantages for Small and Mid-Sized Businesses

- ✅ Cost-Effective: Longer lifespan means fewer replacements and lower operational costs.

- ✅ Increased Throughput: Faster material removal accelerates production cycles.

- ✅ Versatile Customization: Belts can be tailored to fit any machine or application.

- ✅ Improved Surface Quality: Produces consistent finishes that reduce time spent on post-grinding processes.

- ✅ Multi-Environment Use: Functions effectively in dry and wet grinding environments.

Comparison to Other Abrasives Compared to traditional aluminum oxide belts, zirconia belts offer:

- 2–3x longer service life

- More aggressive cut rate

- Better performance on hard metals

- Greater resistance to heat and wear

Zirconia sanding belts are the ideal abrasive solution for high-efficiency, heavy-duty grinding operations. From removing stubborn weld seams to refining forged parts, these belts are trusted by thousands of manufacturers worldwide. zirconia abrasive belts deliver unmatched durability, cutting power, and value.

Reviews

There are no reviews yet.